Let's cut to the chase.

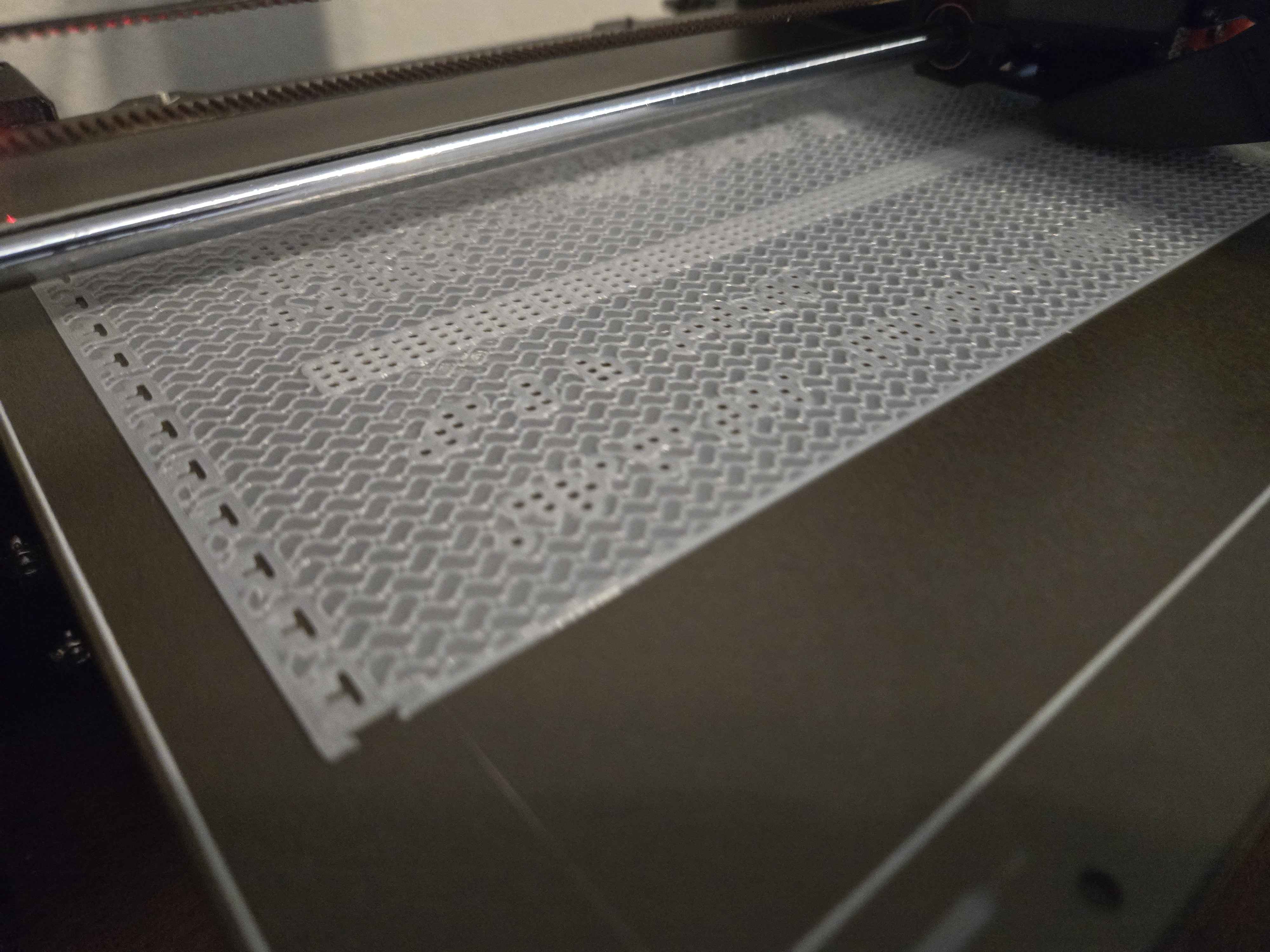

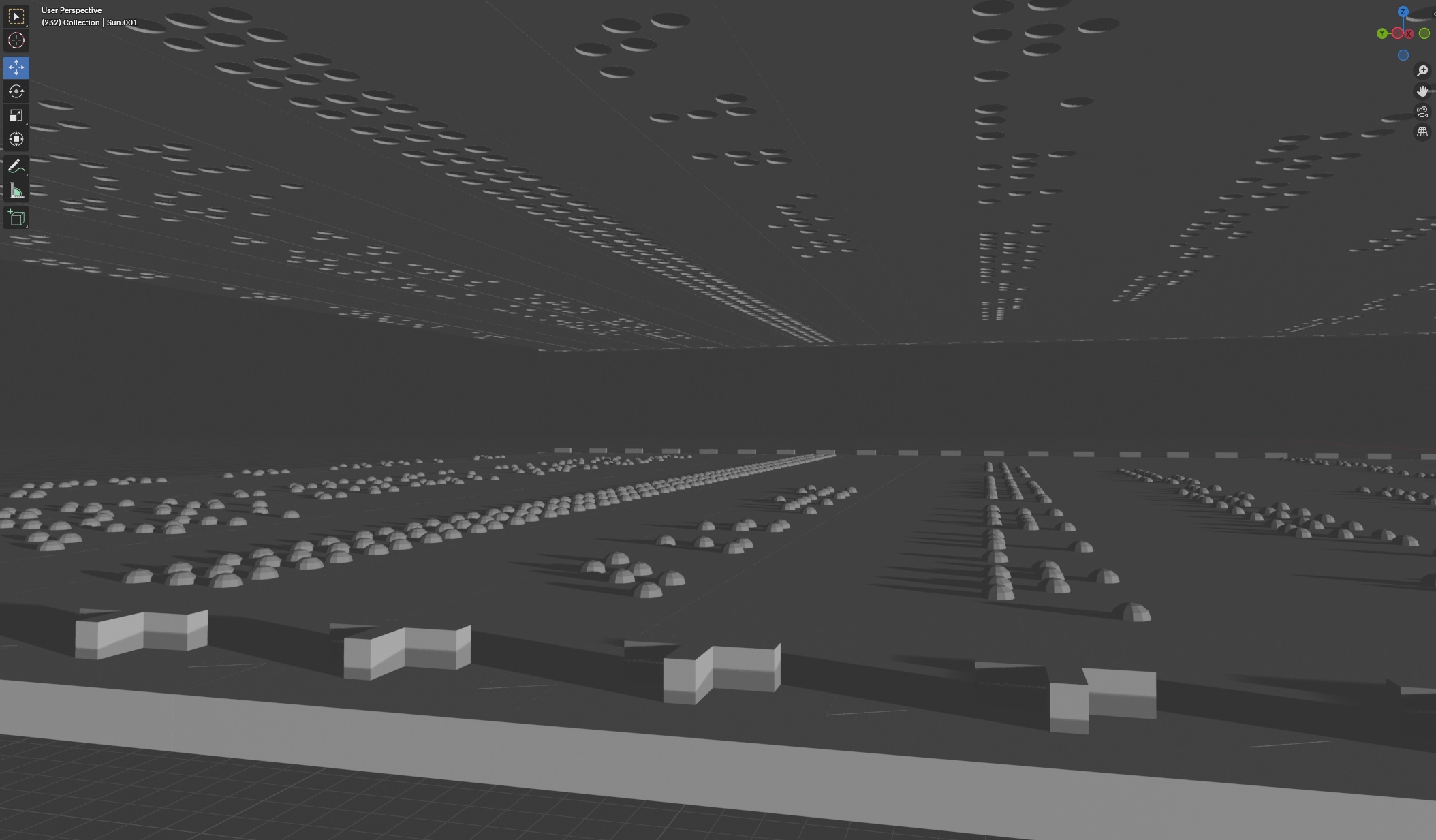

We created some software to convert text into 3D printed molds.

A page mold costs ~1.50 USD in filament.

Molds for a 250 page book costs ~375 USD and requires ~1500 printing hours (@6hr/page).

A page mold is ~6 MB in size.

Molds for a 250 page book takes up ~1.5 GB of space.

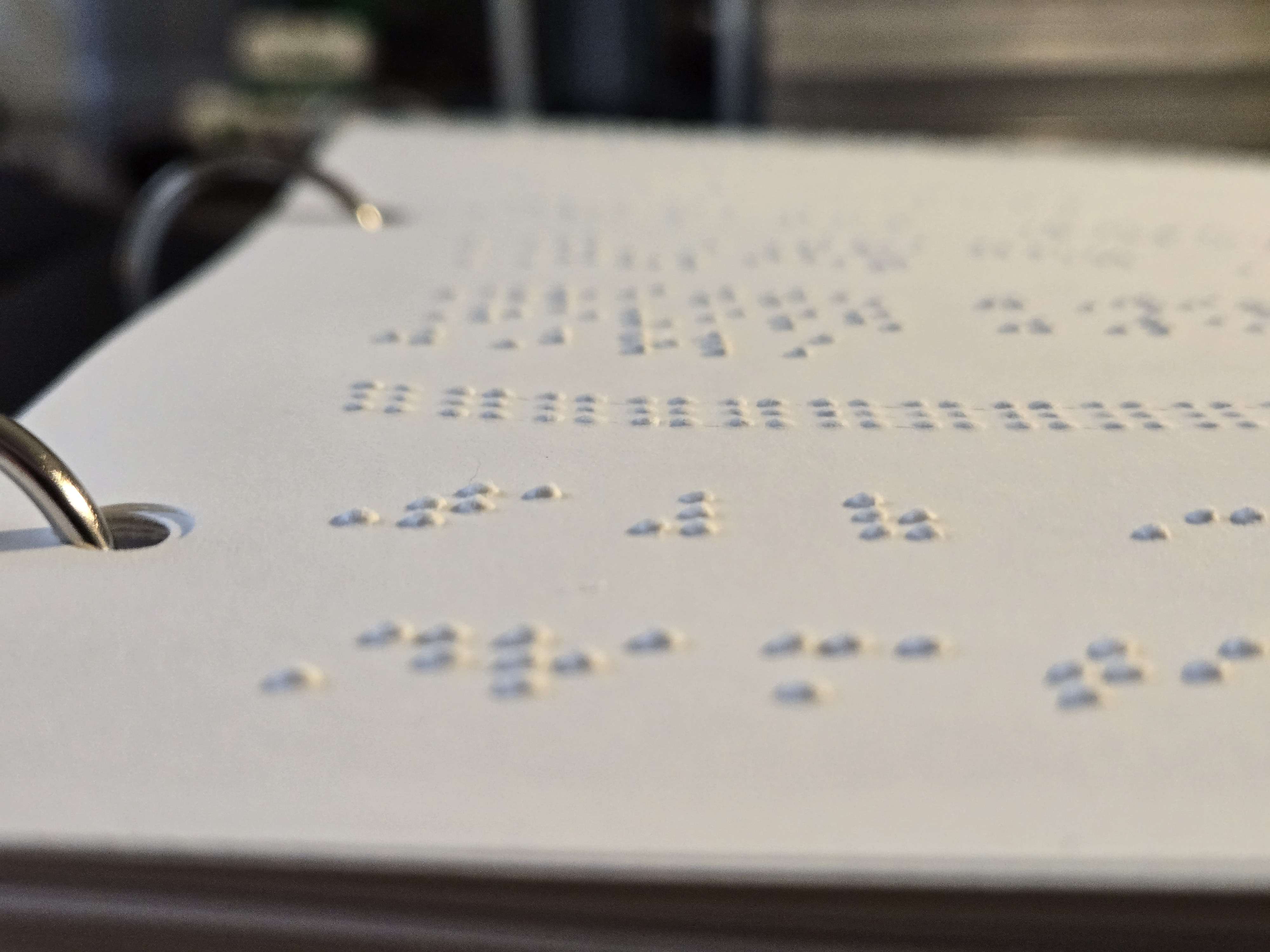

Create stunningly precise works of art.

Repeatably and efficiently emboss entire pages at a time.